ADNN Engineering India Private Limited

ADNN Engineering India Private Limited is a precision engineering company specialising in the design and manufacture of dies and moulds, with advanced capabilities in aerospace and defence component manufacturing.

About ADNN Engineering India Private Limited

ADNN Engineering India Private Limited is a precision engineering company specialising in the design and manufacture of dies and moulds, with advanced capabilities in aerospace and defence component manufacturing. With a strong foundation in tooling solutions, we have evolved into a state-of-the-art manufacturing facility equipped with high-end CNC double column vertical machining Center, delivering high-precision components for various critical applications.

Established in 2021 with the name of ADN Engineering, we have built a reputation for engineering excellence, quality assurance, and on-time delivery, serving a diverse clientele across automotive, aerospace, defence, electronics, and industrial sectors & delivered multiple critical jobs for our customers.

Core Capabilities

1. Dies & Moulds Manufacturing

Design and fabrication of precision injection moulds, press tools, die casting dies, and progressive tools

High-performance CAD/CAM/CAE systems for tool design and simulation

Expertise in complex geometries and tight tolerances

In-house tool trials and validation

2. CNC Precision Machining

3-axis, 4-axis, and 5-axis CNC machining centers for high-precision milling and turning

Machining of hard metals including Titanium, Inconel, Stainless Steel, and Aluminium Alloys

Component manufacturing to AS9100 or ISO 9001 standards

Capable of both prototyping and production volumes

3. Aerospace & Defence Components

Manufacturing of structural parts, brackets, flanges, enclosures, and custom-machined assemblies

Reverse engineering and build-to-print solutions

Compliance with defence industry standards (MIL-STD, NADCAP where applicable)

Traceability, documentation, and inspection aligned with aerospace/defence protocols

Infrastructure

High-End CNC Machines:

Takumi- Complete Details with Photo

John ford- Complete Details with Photo

Hartford- Complete Details with Photo

Design & Engineering Suite: Equipped with SolidWorks, CATIA, Mastercam, and ANSYS

Tool Room & Inspection Facilities: For in-house verification and quality assurance

Environment-Controlled Machining Area: Ensuring thermal stability and machining precision

Infrastructure & Facility

Hurco Takumi BC3025

xis Travel | Unit | BC3025 X axis | mm | 3200 Y axis | mm | 2600 Z axis | mm | 1100

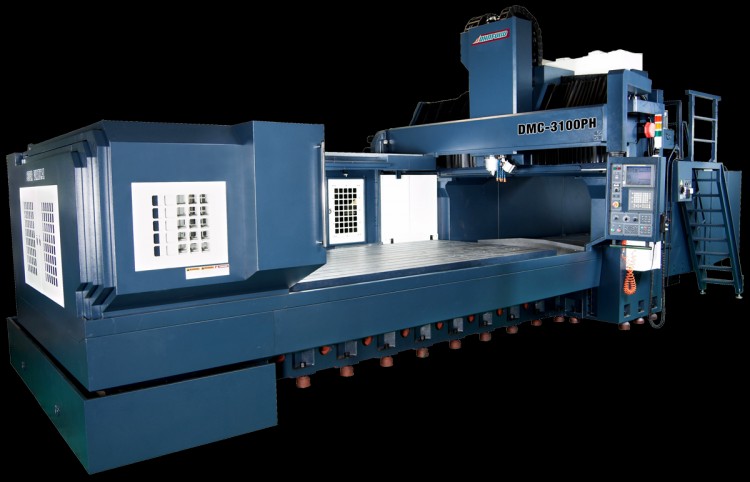

Hartford Cnc Double Column

MODEL: SW-323

Control: MITSUBISHI M720

Table 3,000 × 2,200 mm.

Travel X/Y|Z

3,100 x 2,300 x1070 mm.

Spindle BT-50

Spindle speed 6000rpm.

Max.loading 10000 kg.

Connector memory USB

BT4210

Double Column Vertical Milling Center

Model No: DMC 3100 PH C/w

Control System: Fanuc 18i MC Control

Travel (X / Y / Z): $3100/2300/800$ mm

Speed: $10000$ RPM

Spindle Taper: BT-50

Max Weight: $10$ Ton

Advantage (Adv): For Manufacturing Bigger Size Tools with Accuracy of $25$ microns

Industries Served

Aerospace

Defence

Automotive

Electronics

Medical Devices

General Engineering

Plastic

Infrastructure

Why Choose Us

End-to-End Manufacturing:

Customer-Centric Approach:

Cutting-Edge Technology:

Experienced Team:

Global Standards:

Quality Assurance

We maintain stringent quality protocols backed by:

ISO 9001 / AS9100 certified processes

First article inspection (FAI), SPC, and PPAP practices

Full traceability and material certification

Dedicated QA team with modern metrology tools (CMM, profile projector, surface roughness tester, etc.)

Shova A. Kumar

Founder & Director – Marketing & Financial Planning

Meet Our Leadership

Mr. A. V. Kanse

CEO

Ms. Khushboo Kumari

Promoter

Ms. Monika A. Kanse

Promoter

Business Model